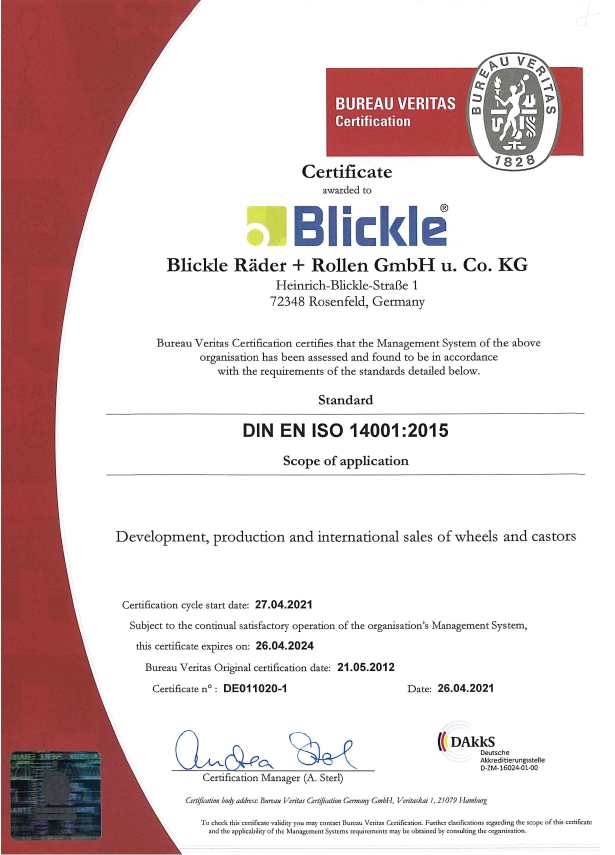

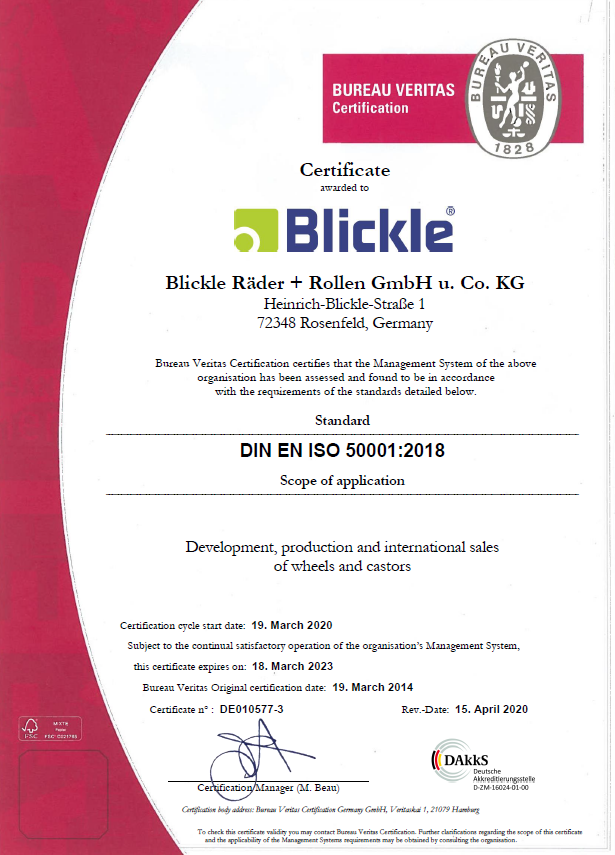

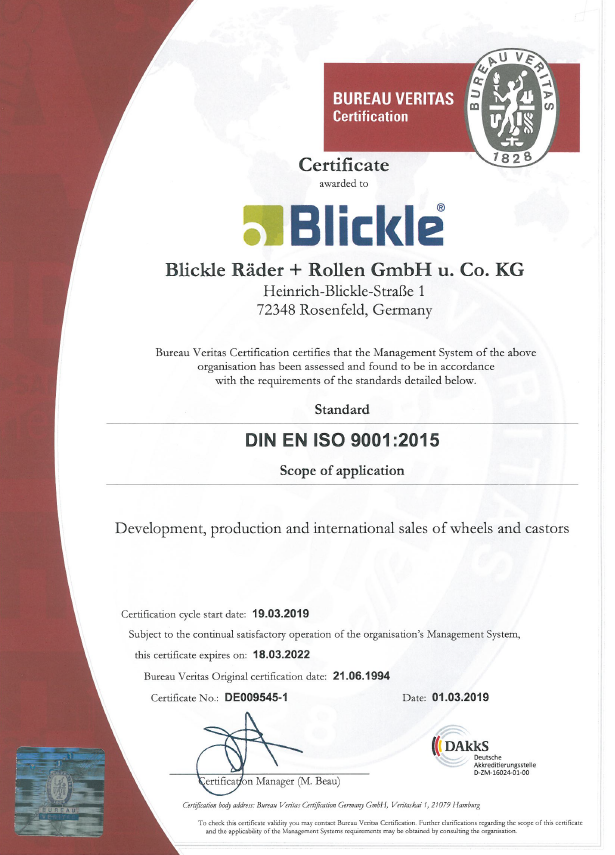

The Quality management is extremely important process for Blickle company, which guarantees high levels of customer satisfaction. Customer confidence is the most valuable asset. Thanks to the use of Blickle own manufacturing facilities and a dedication to products “Made in Germany”, they have full control over the entire process from the start. Blickle was the first German wheel and castor manufacturer to be DIN EN ISO 9001 certified in the year 1994.

The quality management system aims to ensure a high standard of quality in all areas and processes. Comprehensive material and product tests play a crucial role. A multitude of testing devices are available to Blickle’s engineers, including rotary test benches for loads of up to 5.5 t, material testing equipment and climatic exposure test cabinets. They use cutting edge equipment for wheel and castor tests in accordance with DIN EN 12527-12533 in addition to destructive testing. The first and last parts of every production run are always inspected in addition to self-checks by production workers along the way.